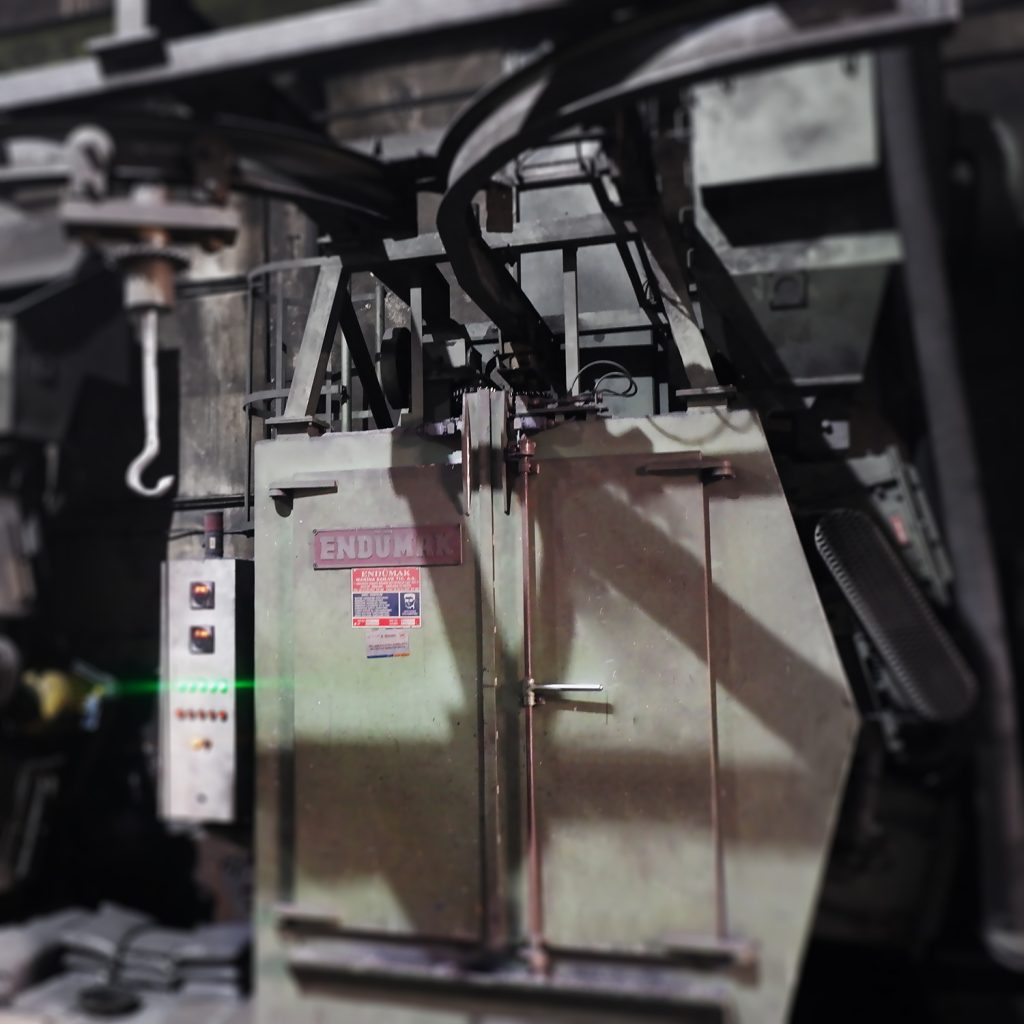

Sandblasting

We carry out the sandblasting process of the casting parts, which are taken from the shakeout machine and still have sand, with two sandblasting machines we have within our structure. The parts taken from the Shakeout Machine are properly placed in specially prepared high manganese baskets and the lids are closed. The process is completed by cleaning the sand residues that may remain on the surface of the part after casting by means of 460 or 560 steel granules (balls) depending on the properties of the part, and by removing the visual differences that may occur on the part surface and giving the part a single surface effect by using the sprinkling method.